|

Return to SOLAR PONDS home page

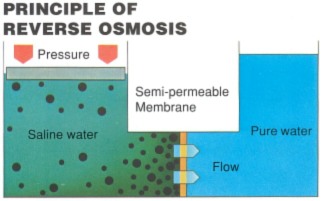

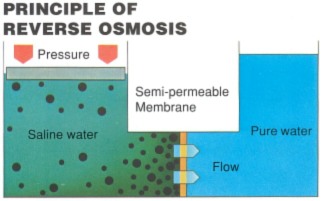

PRINCIPLE OF REVERSE OSMOSIS

|

What is reverse osmosis ?

Reverse osmosis is a method of extracting fresh, drinkable, water from salty, brackish or contaminated water supplies.

Certain membranes called semi-permeable membranes allow water to pass through them but prevent the passage of dissolved salts and other contaminants in the water. A common example of a semi permeable membrane is the casing used to contain sausages.

A tube of semi permeable membrane filled with salty water suspended in a container of fresh water will 'suck' water into itself. This is called 'osmosis' and is the process used (for example) by plants to extract water from soil. Osmosis is a natural phenomenon in which water passes from a relatively dilute solution toward a more concentrated solution if they are separated only by a semipermeable membrane. This flow produces a measurable pressure, called osmotic pressure.

If the process is reversed by applying a pressure to the more concentrated (salty) solution, and if that pressure exceeds the osmotic pressure, water flows through the membrane from the more concentrated solution toward the dilute solution then it is possible to 'filter' salt from water. This process, called reverse osmosis, or RO, removes up to 98% of dissolved minerals, and virtually 100% of colloidal and suspended matter. RO produces high quality water at low cost compared to other purifications processes.

The semi permeable membrane

The membrane must be physically strong to stand up to high osmotic pressure - in the case of sea water, 2.5t/sq m. Most membranes are made of cellulose acetate or polyamid composites cast into a thin film, either as a sheet or fine hollow fibers. The membrane is constructed into a cartridge called a reverse osmosis module. After filtration to remove suspended particles, incoming water is pressurized with a pump to 200 - 400 psi (1380 - 2760 kPa) depending on the RO system model. This exceeds the water's osmotic pressure and allows separation of salt and water.

Pretreatment

Pretreatment is important because it influences the product quality and quantity. It also affects the module's life because many water-borne contaminants can deposit on the membrane and foul it. Generally, the need for pretreatment increases as systems become larger and operate at higher pressures, or as the quality of the incoming water decreases due to suspended particles or biological contaminants.Pretreatment chemicals are sometimes also added to the feed water to prolong the life of the membrane. These may be caustic soda to prevent bio- fouling), citric acid, detergents or disinfectant. .

The products - pure water (permeate) and bypass water (concentrate)

A portion of the water diffuses through the membrane - this is the pure water product of the process - typically water of 200-1000ppm salts can be extracted from much more saline feed water. Some 20-30% of the water does not go through the membrane but is bypassed to a waste stream cotaining dissolved salts and other contaminants. This is the concentrate which is now highly saline and may contain some pretreatment chemicals.

|

|

How does Reverse Osmosis work?

Pressure is applied to saline water to force the pure water molecules through a semi-permeable membrane. The majority of the dissolved salts, organic material, bacteria and suspended solids are unable to physically pass through the membrane and are discharged from the system in the rejected brine. The pure water is then ready for use without further treatment.

|

|

Return to solar pond home page ...... return to top

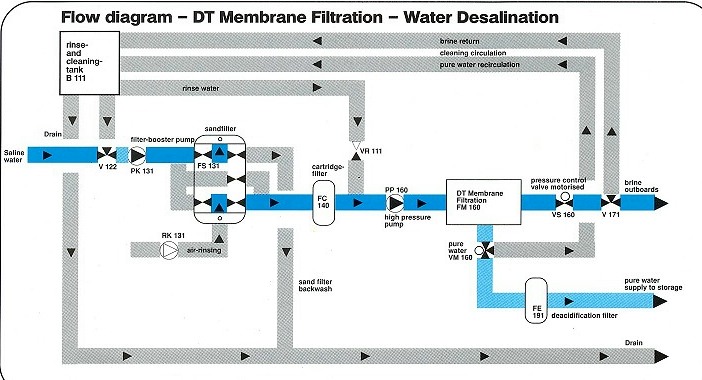

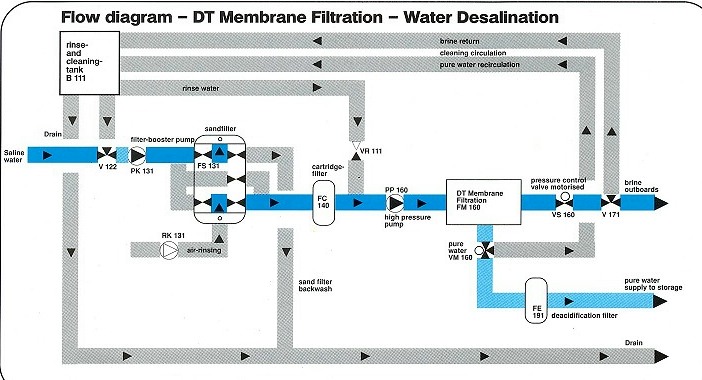

INSTALLATION AND OPERATION

|

Installation

Most RO units are modular and assembled and completely assembled and fully tested prior to despatch from the factory. They can be in full operation literally just a few hours after arriving on site as there are only four fixed or flexible pipe connections to make plus an electrical supply - nothing else.

|

|

|

Operation

|

|

Water pre treatment

The feed pump has a sand filter which needs to be backflushed once a month - this process is manual and is similar to the same process on a home swimming pool. It can be done by unskilled personel after a few minutes training

|

Cartridge filters

These filters are a module system and are cleaned by a fully automated system of flushing with chemicals. The three chemical reservoirs need to be filled once a month and the cartridges will need to be replaced once a month. If the system is to be inpoerative for a week or more, the cartridges will also need to be replaced.

|

|

Membranes

The semi permeable membranes will need replacement approximately once every 5 years. This requires a skilled technician.

|

Annual service

Once a year, the unit needs to be serviced by a skilled technician

|

Return to solar pond home page ...... return to top

Capital and Operating costs of an RO3560 unit

(for details on other available units consult Pall Rochem 61 03 8586 8151)

|

Capital cost(Australian dollars at $1AUD = $0.53US)

Equipped with max of 12 membrane modules - max capacity for this unit. With 12 modules this unit will produce 60klitre.of 500- 1200ppm (potable) water per day

from sea water of 46,000TDS at 25 degree C.

Output improves with higher temperatures up to 40 degrees.

Including installation costs, $240,000 (AUD)

|

Specification of RO3560 unit

Power Supply (kW) 18-25

Dimensions (mm) 3100 x 1800 x 2200

Weight (kg) 70-150

Pure water output

From sea water (klitre /day) 40-60

From brackish water (klitre/day) 40-100

From city water (klitre day) 70-150

|

|

Operating costs

(Australian dollars at $1AUD = $0.53US)

Costs in relation to throughput

Pretreatment chemicals 3c/klitre

Cartridge filters $2.13/klitre

Membranes $1.10 /klitre

Maintenance ??

Electrical power 10kWh/klitre ($1.40/klitre @ 14c /kWh)

|

Cost detail

Chemicals $575/year

Cartridge filters $320 each

(for full replacement 12 x $320 = $3840 every month )

Membranes $10,000 each

(For full replacement $120,000 every 5 years)

Maintenance $25 / hr

(?? hours once a year)

|

|

Cost of water

Cost per klitre (not including power cost) = $1.03

Cost per klitre (including power at 10c/kWh from a solar pond) =$2.03

|

Return to solar pond home page ...... return to top

|